Construimos mejores soluciones gracias a la innovación

Presencia mundial, experiencia local

El mejor aislamiento que podrá tener

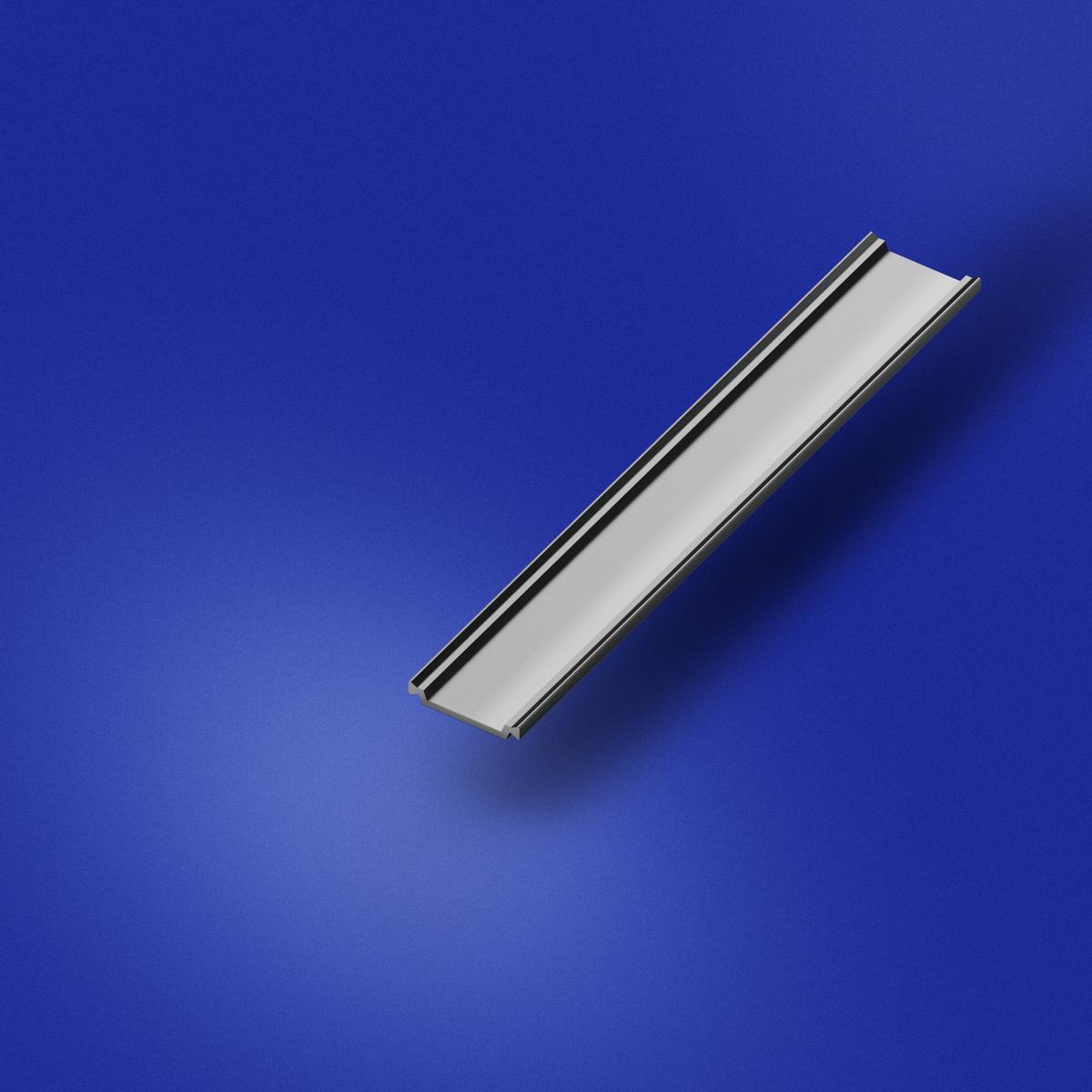

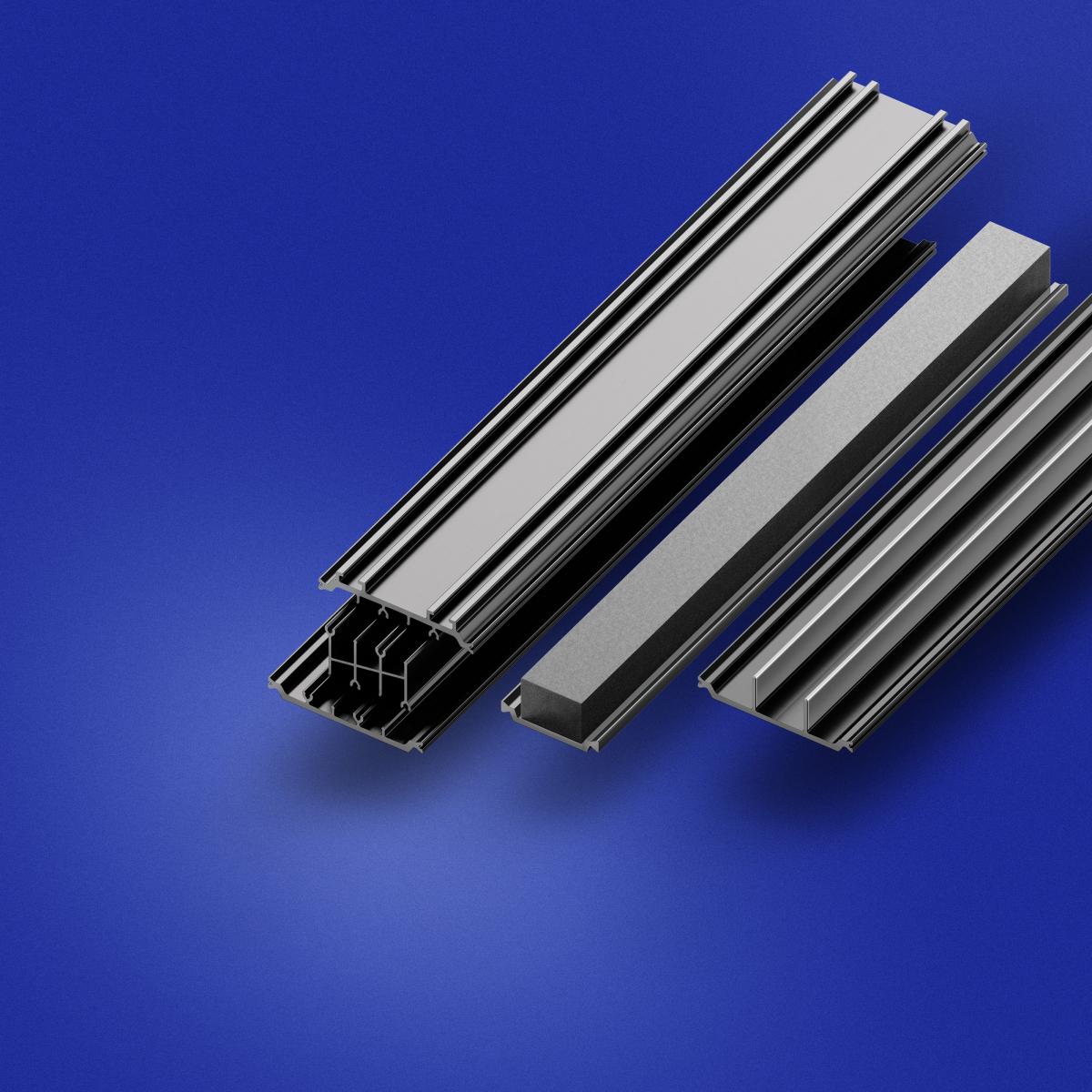

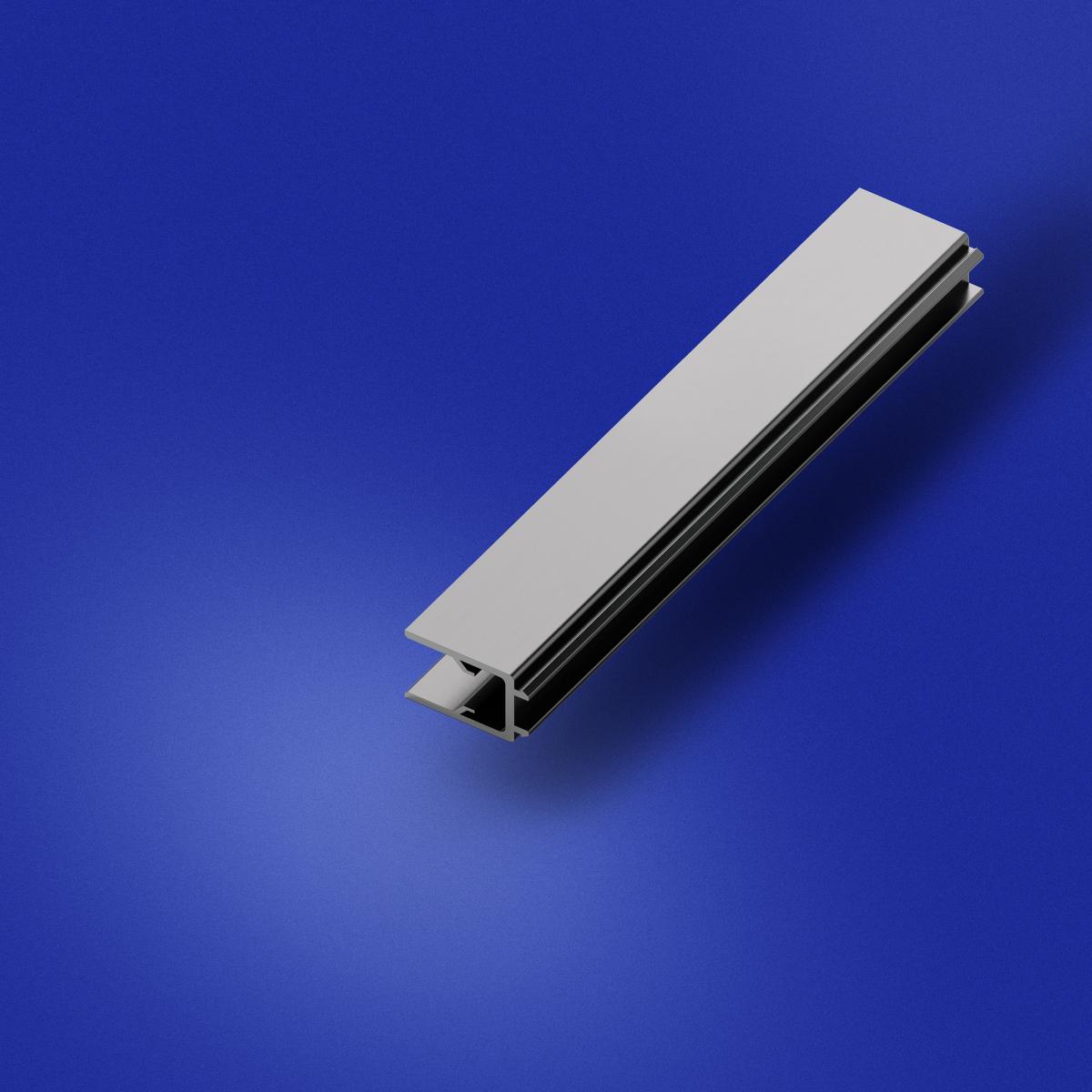

Sin aislamiento, las ventanas, puertas y fachadas de aluminio transfieren frío y calor, y generan una gran pérdida de energía. Es aquí donde entran en juego nuestros perfiles aislantes de alta precisión. Acoplando nuestros perfiles aislantes a paneles y perfiles de aluminio se mantienen las características mecánicas del perfil evitando el paso de frío y calor a través del perfil, efecto que se denomina rotura del puente térmico. El resultado es una conductividad térmica minimizada, eficiencia optimizada y una mejor huella energética. En pocas palabras, separamos el frío del calor creando un clima agradable en el interior de la estancia a unos costes energéticos bajos. Nuestros productos pueden ahorrar hasta el 85 % de energía y reducir de forma considerable las emisiones de CO2. Esto puede equivaler a unos ahorros considerables que se pueden aprovechar con el paso de los años. Además, con nuestra amplia gama de geometrías estándar y soluciones a medida, seguro que encontrará alguna solución que se adapte a sus necesidades, independientemente de la magnitud de su aplicación.

Los retos locales exigen experiencia local. A fin de garantizarle la experiencia adecuada para dar respuesta a sus necesidades, disponemos de centros de producción y oficinas de ventas en todo el mundo. Como empresa familiar, la colaboración y cooperación son la base de nuestro prestigio y nuestros principales valores. Desde hace más de 40 años, somos el socio ideal para desarrollar y optimizar zonas de aislamiento.

Materiales para ventanas, puertas y fachadas

Optimización y uniformidad, sea cual sea la necesidad que tenga. Conozca más sobre los materiales capaces de revolucionar sus construcciones.